How Much Do You Know About Rail Joint

Steel rail is the main component of rail track, while the function of rail joint is to connect steel rails together. The application of rail joint helps to attribute the development of railway industry. Rail joint can be classified into many types, including compromise rail joint, insulated rail joint, glued insulated rail joint.

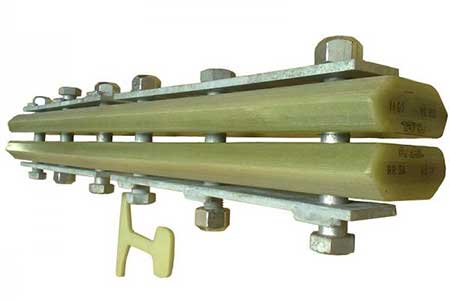

Insulated and Non-insulated Rail Joint

Common railway joint is electricity conductive and it is made of metal material, while insulated rail joint is made of insulated material and it’s electricity-insulated.

Features of Insulated Rail Joint

- It has the features of corrosion resistance, UV-resistance, Non electricity conductive and non magnetic conducting.

- The material can protect the insulated rail joint from rust, which can prolong the service life and ensure the safety of railway.

- The material belong to thermoset material, it can’t be reused by second processing.

- The quality testing of insulated rail joint must be ordering to strict inspection standard, so insulated has high strength.

Features of Common Rail Joint (Non-Insulated Rail Joint)

- Electricity conductive and magnetic conductive in railway track.

- The material belong to high strength steel and bolted to the end of the steel rails.

- Be able to bear the vertical and lateral force from the steel rail.

The Requirement When Fasten Rail Joint to The Steel Rail

Railway joint plays great importance in fastening steel rails, so it need to fix the rail joint and ensure the quality of rail joint and guarantee the safety of railway.

- The rail joint should be fastened by the matched fish bolt to the steel rails. There should no crack on the surface of the rail joint and the fastening set.

- Each of the connecting rod lock and the fish bolt should have no crack and abrasion before installing. The abrasion of pin hole shall be less than 1mm.

- The iron rod is connected with good insulation material, external lock iron and connecting rod is connected with said iron of good insulation. If no insulation material, please keep at least 3mm gap and don’t get in touch with other parts.

- Check if there is crack on fishplate shell device switch machine, or the machine can work well with good fastening or locking effect.

- Check out if the protective measures of oil tank are complete, and whether it is buried by ballast and other sundries.

How to prevent the rail joint from cracking?

The weather and temperature may influence the quality of rail joint and may cause the cracking of rail fish plate. How to protect the railway joint from cracking is important, now we will introduce some ways to prevent the rail joint from cracking.

- As for the rail joint in warm areas, it’s better to make the thickness 190mm, which can make the RL—FL in the same level and be convenient to fasten and operate on the railway track.

- As for the cold areas, it’s better to prevent the rail joint from immerge of the rail and snow, which can protect the rail joint from the severe cold.

- Compare with PC structure, PRC structure is more reliable to reject prestressing into the structure of rail joint due to the rigid and strength of rail fish plate.

Guarantee the safety of railway and secure the normal movement of trains is especially important in rail track, so it’s vital to ensure that rail joint is in well work and be fastened tightly to the steel rails.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!