How to Prevent Screw Spike from Corrosion

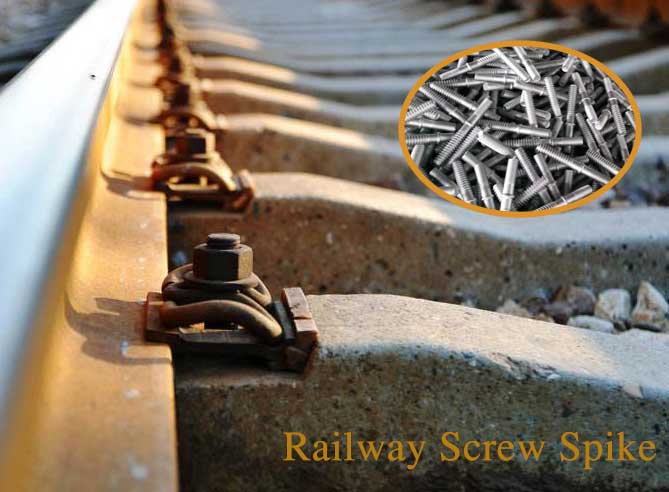

Railway spikes are a kind of fastener for connection of rails, rail pads, rail sleepers or rail tie plates to the sleepers. Railway screw spike is a kind of railway spikes for fastening rails and pre-stressed concrete sleepers. It is usually used with the rail plastic sleeve which is fixed on the reserved holes of the concrete sleeper through sulfur anchor. The upper bolt is used for fixing parts (for example, rail clamp, elastic clip, etc.).

Material Used for Screw Spikes

In China, the most common material of screw spikes is Q235A Steel. Q235A steel is an ordinary carbon steel. To be exactly, Q represents yield limit of the steel; 235 refers that the yield value of this material is 235MPa. Q235A steel has good toughness and excellent flexibility with the certain elongation, so it has good performances of welding and hot workability. Q235A steel is generally used in the hot rolled state. Here A stands for no requirement of the impact ductility test.

Chemical Composition of Q235A Steel Mainly is as Follows:

|

C |

Si |

Mn |

S |

P |

Cr |

Ni |

Cu |

|

0.14-0.22 |

≤0.30 |

0.30-0.65 |

≤0.050 |

≤0.045 |

allowed residual content≤ 0.030; |

allowed residual content≤ 0.030; |

allowed residual content≤ 0.030; |

Mechanical Properties of Q235A Steel are Mainly as Follows:

As relevant standards of China, the upper thread of screw spike is M24; the down thread is special M25.6×6-d24.0/25.6. For the thread, it is as high as 3.25mm-0.25mm.

Technical Requirement of Rail Screw Spike

-

The forging crack of truncated-cone-type of surface of the screw spike cannot be allowed to extend to the screw rod.

-

The upper thread of screw spike cannot be allowed to be with the impact and burr that will cause thread gauge to fail in screwing in freely. Meanwhile, the double cusp, scratches and incomplete thread is prohibited.

-

The plastive sleeve shall be manufactured in uniform with complete thread and no splitting traces.

-

The surface of screw spike cannot be allowed to be with burr, rag, burn and oxide scale.

-

The screw spike shall also be really tested for tensile strength. When the load is 130kN, the screw spike shall not get broken and have a very good effect.

How to Prevent Screw Spike from Corrosion?

The screw spike is one of the important

railway accessories. Because of long-term exposure in the air, facing the long-term erosion of rain water and other waste water and relatively poor environment, it is prone to have corrosion problems after a long time of use. And then, what should we do to avoid corrosion problems? Here we, as a professional spike manufacturer, are introducing anti-corrosion method.

-

To Use Non-sulfur Anchor Material

At present in China the main anchor material of the screw spike adopts sulfur anchor agent popularly. The sulfur anchor agent is convenient and fast in working operation, but of the sulfur anchor agent, there is HS, S2, SO2 and the others that can make the screw spike have serious corrosion when they combined with water will arouse the chemical changes of acid electrolyte solution. In addition, as using sulfur anchor agent, it has to use the fire to brew the sulfur, which will pollute the environment of railway and is bad for crops due to smoke. By comparison, we need better materials that the ingredients are environmentally friendly material. If we choose hydraulic hardening material of 525 white portland cement to be as the anchoring material and adopt emery aggregate as a new type of water soluble anchoring agent with a certain amount of anti-rusty agent. And then, when the preparation of non-sulfur anchoring agent on the working site, we will only do the stirring as the formulation of various materials and the proportion, which will achieve requirements of not less than 60kN of anti-pulling force and anti-corrosion of the screw spikes.

-

Long Effective Anti-corrosion Grease

Screw spikes work in environments of coldness, wind, rain and high temperature that usually contain O2, SO2, C12 and other corrosive media. They are also affected by the axial vibration and radial torsion force. So the ordinary anticorrosive grease cannot meet the needs and has to add anti-corrosion, solid, antioxidant and metal deactivator, anti-rusty agent in order to improve the anti-rusty and anti-corrosion grease and make them be adapt to different requirements of protection.

-

To Standardize Anchoring Technology

Using a non-sulfur anchor agent, screw spikes should be installed with the anchor frame in accordance with the requirements to ensure the position of the railway spikes accurately. At the time of anchoring, we should also clean up the spike holes and pour enough solution, which should be not too full and not too little. The anchoring truncated cones of screw spikes shall be 0-2mm higher than the surface of concrete sleeper (as using elastic clip), the holes should be fully filled. When anchoring solution becomes into the solidification, we should clean anchoring agent that has overflowed to avoid uneven, which is easy to make water stay there and cause corrosion.

The keys of the maintenance of anti-corrosion of screw spikes are determined by material selection and installation. These will help to lay the foundation for the normal use of the screw spikes.